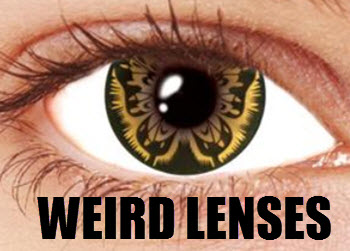

Introduction to Decorative Eye Lenses

Decorative eye lenses, often referred to as cosmetic or colored contact lenses, have gained significant popularity for both cosmetic and theatrical purposes. Unlike regular corrective contact lenses designed to improve vision, decorative lenses are primarily used for aesthetic enhancements. They not only enhance or change eye color but also enable users to achieve various looks, ranging from subtle changes to dramatic transformations. As fashion and self-expression evolve, more people find unique ways to complement their appearance, and these lenses provide a relatively simple yet effective means to do so. The variety of colors and designs available cater to diverse preferences, whether one is aiming for a natural eye color enhancement or a bold, theatrical look. Moreover, the materials used in manufacturing these lenses are crucial for user comfort, safety, and visual effectiveness, ensuring that they don’t just look good but are also safe and comfortable to wear.

Basic Components of Decorative Eye Lenses

Many decorative eye lenses are made from similar materials to corrective lenses, although specific components may vary depending on the desired appearance and usage. Generally, the primary materials used are chosen for their oxygen permeability, durability, and comfort. Given that these lenses are worn directly on the eye, material selection plays a crucial role in ensuring the wearer can enjoy the lenses without sacrificing eye health and comfort.

Hydrogel Polymers

Hydrogel polymers are among the most common materials used in the construction of decorative eye lenses. These polymers are renowned for their ability to contain a significant amount of water, which effectively helps the lens remain soft and comfortable when placed on the eye. The hydrophilic (water-attracting) properties of hydrogel materials make them ideal for prolonged wear. One of the most well-known hydrogel polymers is HEMA (hydroxyethyl methacrylate). HEMA is celebrated for its balanced flexibility and ease of handling, which simplifies both the manufacturing process and the user’s experience. Comfort being a primary consideration, hydrogel polymers ensure that users can wear the lenses for extended periods without experiencing discomfort or dryness.

Silicone Hydrogel

Silicone hydrogel lenses represent an advanced version of traditional hydrogel lenses. By combining hydrogel’s comfortable properties with silicone, these lenses allow for significantly higher oxygen transmissibility. The inclusion of silicone increases the breathability of the lens considerably, which is a substantial advancement as it enables longer lens wear without compromising the health of the eye. Importantly, these lenses are ideal for users desiring to wear decorative lenses frequently or for extended periods. The ability to cater to longer usage periods makes silicone hydrogel lenses a preferred choice for many, providing both aesthetic appeal and ongoing comfort.

Rigid Gas Permeable (RGP) Materials

RGP materials, though less commonly used in decorative lenses due to their inherent rigidity, offer certain advantages. These materials are utilized in specialty lens applications, allowing oxygen to pass through to the cornea, though not as effectively as the silicone hydrogel variants. However, what RGP lenses may lack in flexibility, they make up for in durability and the quality of vision provided. The sharper vision and longevity provided by RGP lenses can be particularly useful for specific theatrical applications where detail and clarity are paramount.

Color and Design Application

The inclusion of color in decorative lenses requires specific manufacturing techniques designed to ensure that pigments are securely embedded within the lens material. This design prevents direct contact with the eye, thus maintaining ocular safety while achieving vibrant colors or unique patterns. Such preventive measures help maintain the integrity of the eye’s natural barrier, ensuring that the lenses are both safe and visually appealing.

Layered Pigmentation

The majority of decorative lenses utilize a multi-layer coloration process. This process involves the careful placement of color between layers of the lens material, providing additional protection and ensuring that the vibrancy of the color does not diminish easily over time. Advances in printing technology have contributed significantly to the creation of more natural appearances and intricate designs, allowing users to choose from a wide array of aesthetic effects. The embedding of color in layers further ensures the lens’s durability and the vibrancy of designs, enhancing both practicality and visual appeal.

Dot Matrix Patterns

The use of dot matrix patterns in decorative lenses allows them to replicate the intricate, natural patterns of the human iris, enhancing realism. This technique involves the precise arrangement of small dots on the lens, maintaining the wearer’s vision clarity by ensuring the central part of the lens remains clear. Dot matrix patterns offer a higher degree of naturalness and are an essential feature of lenses designed to subtly alter eye color while maintaining a lifelike appearance.

Safety and Regulatory Considerations

Safety and regulatory compliance are crucial when it comes to choosing decorative eye lenses. In various regions worldwide, including the United States, decorative lenses fall under the category of medical devices. This classification necessitates approval from governing bodies such as the FDA (Food and Drug Administration). Such oversight ensures that the lenses meet strict safety standards and are free from harmful substances that could jeopardize users’ eye health. Users must remain informed and vigilant when selecting lenses, preferring only those that adhere to such regulations and ensuring compatibility with their individual needs and conditions. This way, potential complications are minimized, and the joy of altering appearance through decorative lenses can be experienced safely.

Conclusion

The development of decorative eye lenses combines meticulous selection of materials with advanced manufacturing techniques, all designed to ensure comfort, safety, and aesthetic appeal. By understanding the materials used in their manufacture, consumers can make informed choices, ensuring optimal satisfaction and protection of eye health. From the more common hydrogel to advanced silicone hydrogel materials and specialty RGP applications, each option offers unique benefits suited to diverse preferences and needs. As decorative lenses continue to evolve, users are presented not only with a wider range of visual effects but also with advancements that promise enhanced safety and comfort.

Cosmetic contact lenses

Cosmetic contact lenses